Improve Material Handling Efficiency & Save Space

-

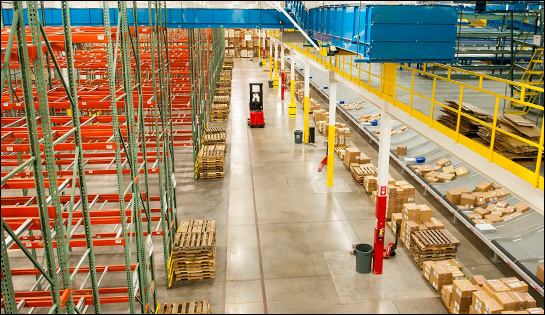

Automated Storage and Retrieval Systems (AS/RS) offer a faster, more efficient way to move goods through your facility using horizontal and vertical storage carousels. By eliminating forklift trips down storage aisles and wasted travel time between widely placed racking, AS/RS allow you to run more efficiently and adjust your racking to save storage and floor space.

Loads—big or small—are moved automatically between drop-off and retrieval locations where they are picked up by lift trucks or other equipment. Movements are tracked and recorded in real time using RFID tags, simplifying inventory management, and reducing the need for storage audits.

The Ideal Solution for Your Facility and Application

-

Raymond’s strategic partnership with Bastian Solutions allows us to offer a full suite of industry-leading AS/RS options as part of our complete lineup of integrated systems and technologies.

By eliminating the need for forklifts to handle certain movements of goods through your facility, AS/RS allow you to make your aisles narrower, saving valuable space and increasing capacity.

They also let you designate specific locations for inventory retrieval, streamlining processes and controlling traffic to optimize throughput when demand is high. -

Unit Load AS/RS

Move standardized unit loads specific to your facility, ideal for high-throughput, high-density storage spaces.

Mini Load AS/RS

Ideal for operations looking to save floor space for their smaller products, these systems can be installed in aisles as narrow as seven feet and can operate at multiple rack heights to deliver retrieved items to a single first-level access point.

Pallet Shuttle AS/RS

Move whole pallets of goods between specific warehouse storage locations and retrieval points.

-

Radioshuttle System - Flexible, High Density Storage

This semi-automated high density storage system allows for a maximum use of warehouse space, maintains selectivity between all levels and increases operational efficiency.

The Radioshuttle is loaded into storage loads and, taking commands from the remote control, executes orders to load or unload pallets into a lane. The lanes are fed pallets by lift trucks such as reach trucks or counterbalanced forklifts.

-

Flexible Alternative or Addition to AS/AR Systems

The Raymond Automated Transtacker has dual-mode capability – able to be used in automated mode for full pallet handling or manually operated for case picking. The Transtacker solution combines the space and labor-saving benefits of AS/RS systems with the flexibility to change aisles when needed using the manual mode.

Contact us today to learn how the Automated Transtacker uses no special racking – just your existing infrastructure.

-

Optimization Before Automation

Before introducing automation into your business, your warehouse and processes should first be analyzed and optimized. Raymond Solutions & Support Centers can help lay the groundwork for a successful implementation by introducing our unique Lean Management System and by assessing everything from your facility layout to racking systems and forklift integration.

Advanced computer technologies are used to consider structural specifications, expected routes, material touchpoints, and more to create a warehouse that optimizes every interaction between associates, automated systems, and lift trucks.

Technologies and Services Related to AS/RS

-

Conveyors & Carousels

The right conveyor system can speed up order fulfillment, provide better inventory management and help accomplish lean goals for just-in-time and process controls. Learn More -

Industrial Robotics

Industrial robots can be designed and programmed to facilitate picking, packing, and palletizing in your warehouse. Learn More -

Engineering Services

Our comprehensive engineering services ensure accurate design, installation and planning of your project — and accommodate any changes or alterations along the way. Learn More